Waste streams are full all sorts of interesting things – one of which is an enormous amount of food. In fact, food waste represents 13-15% of the stream . Many US cities, including Philadelphia, New York and San Francisco, have set zero-waste-to-the-landfill goals. If those cities were able to positively extract 15% of the waste stream, they would be well on their way to meeting those goals. If they were able to then process that waste locally – creating jobs and reducing transportation costs – even better. Upcycling that food waste into useful products that could be sold and used locally would be even better – and would support the development of a strong circular economy that substantially reduces landfill bound waste with its accompanying disposal fees, creates even more jobs, and strengthens local communities by improving the economic and environmental health of the city.

This is the promise of RNG Energy’s Point Breeze Renewable Energy Project (PBRE) that is planned for a late 2019, early 2020 start-up on a 22-acre parcel at the Philadelphia Energy Solutions Refining Complex in Philadelphia. The PBRE project which is currently in pre-permit discussions with PA DEP and the City of Philadelphia, plans to construct a series of anaerobic digesters that will have the daily capacity to process up to 1,400 tons of food waste slurry into two marketable outputs: Renewable Natural Gas (RNG) and Organic Materials Review Institute (OMRI) certified organic solids.

The City of Philadelphia is no stranger to this technology. The Philadelphia Water Department currently operates 20 anaerobic digesters; 12 at its Southwest and 8 at its Northeast Water Pollution Control Plants. At these plants both biogas and biosolids are recovered from the processing of waste water and aircraft de-icing fluid from Philadelphia International Airport.

The City of Philadelphia is no stranger to this technology. The Philadelphia Water Department currently operates 20 anaerobic digesters; 12 at its Southwest and 8 at its Northeast Water Pollution Control Plants. At these plants both biogas and biosolids are recovered from the processing of waste water and aircraft de-icing fluid from Philadelphia International Airport.

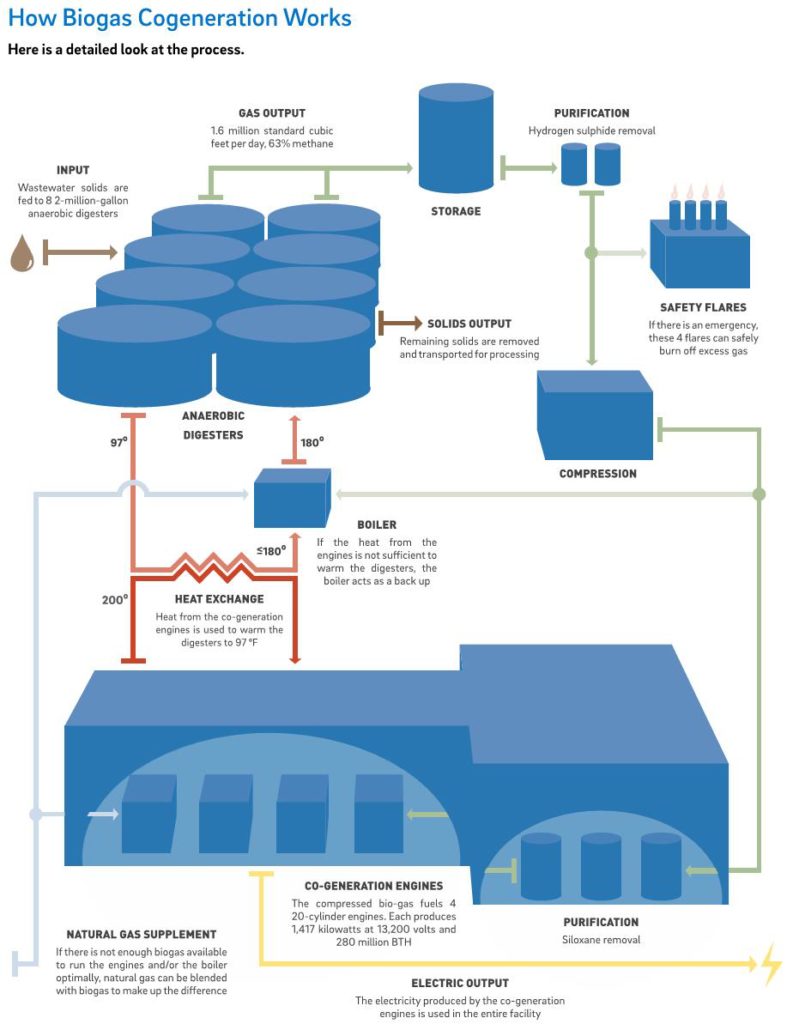

At the Southwest plant, the biogas is burned to heat the plant and to dry and peletize biosolids to market as both fertilizer and alternative renewable fuel. Production and marketing of these biosolids are managed by a contract with Synargo Technologies at the Philadelphia Biosolids Recycling Center (BRC). At the Northeast plant, the biogas is used to fuel a cogeneration facility that captures and burns methane to produce up to 85% of the plant’s electrical needs or 43million kWh, and all of the plant’s process heat needs. The digested solids are shipped to the BRC facility plant for processing by Synargo.

The RNG Energy PBRE project anticipates providing the capacity to manage the commercial food waste generated within Philadelphia that is not processed through waste-water-system-connected grinders and to accept organic material from regional sources as far away as 60 miles from the plant. Where PWD’s anaerobic digesters are mainly fed via the city’s waste pipe infrastructure, the PBRE digesters will accept liquified, ‘de-packaged’ organics via tanker trucks. Waste from restaurants, cafeterias, grocery stores and food processor plants, will be collected by commercial waste haulers and brought to satellite ‘de-packaging’ transfer stations where organics will be separated from food related materials like packaging, trays, and utensils. After separation, water will be added to create a pumpable slurry that is ready to be fed into the digesters. The separated, non-organic material will then be sorted into recyclable and non-recyclable material and processed accordingly.

Like the PWD digesters, the PBRE will upcycle the liquified waste into biogas and digested solids. RNG Energy anticipates that the raw biomethane will be 60% methane and that this will be upgraded to a more marketable level by a supplemental process to 97-99% transportation grade methane for pipeline injection. The 300-340 cubic yards per day of solids material generated in Philly will then be marketed to large scale soil amendment and compost companies. At its Colorado facility, RNG Energy had secured Organic Material Review Institute (OMRI) organic certification for its digested solids and the firm anticipates receiving this same level of certification for PBRE generated solids.

Heartland Project in Colorado Picture courtesy of RNG Energy

Heartland Project in Colorado Picture courtesy of RNG Energy

The city’s Dumpster Laws, requires:

- Requires all food-handling establishments install garbage disposals to grind non-packaged food waste

- Prohibits such establishments from placing grindable food waste in dumpsters

- and requires them to arrange for private collection of non-ground food waste for composting, anaerobic digestion, or use as farm livestock feed.

Complementing this, all new residential construction is required to install in sink food waste disposers, and all residents – in new and old construction – are encouraged to dispose of food waste through the city waste water system.

Heartland Picture courtesy of RNG Energy

Heartland Picture courtesy of RNG Energy

Even with these regulations and practices only a fraction of the food waste is captured. The problem is that since the 2014 closure of the Wilmington, DE organics management plant for code and odor violations, there are no large scale – tons of material a day – composting facilities in the Philadelphia region. The PBRE project would provide capacity to make the dream of organics diversion come true and would allow regulated requirements to be met.

Philadelphia has taken a national leadership position in sustainability by demonstrating the political will to make sustainable solutions a priority in city decision making by putting in motion key initiatives; In 2017 the city set the goal of zero waste to landfills by 2035 and set the goals of cutting carbon emissions by 50% and procuring 100% of electricity from clean energy sources by 2030. This has set the stage for attracting circular economy solution investments that help the city meet its sustainability goals while growing construction and long-term jobs, building the industrial base, and developing new products that use local raw materials, in this case waste, that are marketable locally and beyond all while bringing the city one step closer to its Zero Waste goal.

Looking forward to taking a tour and pictures of RNG Energy’s Phily biodigesters!

Footnote 1.: The PWD has determined that it has an undisclosed amount of excess capacity at its biodigester plants and in 2017, posted an Request for Information (RFI) for vendors who could supply tanker loads of pre-processed, liquified food waste to one of the digester plants for a demonstration project to determine the feasibility of adding food waste slurry as an input to its processes.

Footnote 2: RNG Energy holds a 20% share of the Heartland Project. It had been mothballed due to a legal battle but new majority owners plan to restart the digester process and get the plant humming again.